Metal Building Resources for Architects

Are you an architect or someone planning to design their own build? You’re in the right place. Below you’ll find standard trim details, steel details, and wall sections that you can use to design your structure. There’s also information about common panel profiles and color options.

Wall Sections

These common cross-sections and details demonstrate how our structural systems integrate with metal, tilt-up, or masonry walls. We’ve also included common roof and base condition details.

We’re sharing these details for project planning purposes only. They are not intended for construction. You’ll receive specific details for your project once the order is placed.

Standard Steel Details

Roof Secondary

RA – Low Eave

RB – High Eave (Single Slope)

RC – Rake Details

RD – Purlin Bracing

RE – Roof Framed Openings

Valley and Parapet Gutters

Liners & Partitions

PA – Flange Brace w/ Liner

PB – Base Details

PC – Partition Framing

Standard Trim Details

PBR Roof

R0 – General Details

RA – Low Eave

RB – Rake

RC – Ridge

RD – High Eave

RE – Parapets

RF – Valley & Parapet Gutters

RG – Eave & Rake Extensions

RH – Translucent Panels

RI – Canopies & Lean-tos

SSR - Trapezoidal Rib

TA – Low Eave

TB – Rake

TC – Ridge

TD – High Eave

TE – Parapets

TF – Expansion Joints

TG – Valley & Parapet Gutters

TH – Translucent Panels

TI – Roof Curbs

TJ – Eave & Rake Extensions

TK – Canopies & Lean-tos

Liners & Partitions

LA – Wall Liner

LB – Base Details

LC – Ceiling Liner

LD – Framed Openings

SSR - Vertical Rib

VA – Low Eave

VB – Rake

VC – Ridge

VD – High Eave

VE – Parapets

VF – Expansion Joints

VG – Valley & Parapet Gutters

VH – Roof Curbs

VI – Eave & Rake Extensions

VJ – Hips & Valleys

VK – Canopies & Lean-tos

Eave Extensions & Soffit

Color Chart

Panel Paint Comparison

Polyester (Good)

Hard and resistant to scratches

Prone to chalking and fading

Least popular finish for exterior paneling

Lowest price point

Silicone Modified Polyester

Typically contain 30% silicone in the resin to improve gloss, fade resistance, and chalking resistance

Improved scratch resistance when compared to Kynar

Mid-level price point and performance

Fluoropolymer/PVDF aka Kynar 500® (Best)

Best gloss retention and protection against fading and chalking

Softer paint than SMPs so the paint is more flexible

Less likely to fracture during panel manufacturing than SMP counterparts, but also less scratch resistant

PVDF (Polyvinylidene fluoride) must be 70% of the total resin content

Most costly option

| Color | Solar Reflective Index (SRI) |

|---|---|

| Solar White | 86 |

| Bone White | 85 |

| Snow White | 78 |

| Almond | 77 |

| Polar White | 70 |

| Light Stone | 65 |

| Aztec Gold | 61 |

| Galvalume (Clear) | 56 |

| Brownstone | 55 |

| Regal Red | 55 |

| Saddle Tan | 53 |

| Ash Gray | 52 |

| Desert Tan | 47 |

| Crimson Red | 42 |

| Slate Gray | 40 |

| Charcoal | 39 |

| Rustic Red | 38 |

| Koko Brown | 37 |

| Evergreen | 37 |

| Colony Green | 37 |

| Medium Bronze | 36 |

| Burnished Slate | 35 |

| Classic Green | 33 |

| Colonial Red | 31 |

| Hawaiian Blue | 31 |

| Midnight Bronze | 29 |

| Black | 28 |

| Fern Green | 28 |

| Gallery Blue | 27 |

| Burgundy | 27 |

Common Panel Profiles

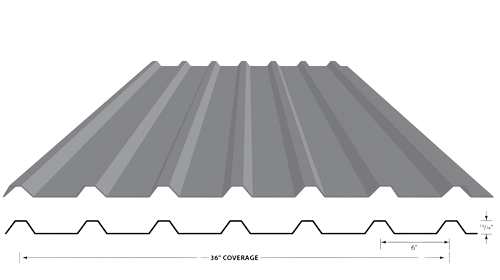

PBR

Traditional exposed fastener R-Panel profile with a purlin bearing leg. Major ribs are on 12″ centers. The area between the major ribs is reinforced with two minor ribs for added strength and stability.

Used for: Roof, walls, liner, and soffit

Coverage - 36″

Major Rib Height - 1-1/4”

Rib Spacing - 12” OC

PBU

Traditional exposed fastener U-Panel profile with a purlin bearing leg. Uniform ribs are on 6″ centers.

Used for: Roof, walls, liner, and soffit

Coverage - 36″

Rib Height - 3/4”

Rib Spacing - 6” OC

Ag Panel

Exposed fastener roof with major and minor ribs for added strength and stability.

Used for: Roof, walls, liner, and soffit

Coverage - 36″

Major Rib Height - 3/4”

Rib Spacing - 9” OC

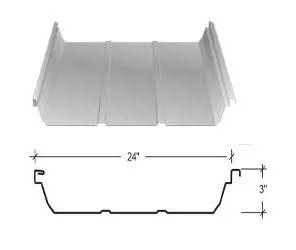

Standing Seam - Trapezoidal

Concealed fastener roof panel that attaches to the structure with a hidden clip system. The roof side lap seams are trapezoidal, giving the panel its name.

Used for: Roofs

Coverage - 24”

Seam Height - 3″

Standing Seam - Vertical

Concealed fastener roof panel that attaches to the structure with a hidden clip system. The roof side lap seams are trapezoidal, giving the panel its name.

Used for: Roofs

Coverage - 16”

Seam Height - 2″